Why I returned the Monorim G30 MAX Suspension

After getting a Ninebot G30, I decided to attempt to make the ride more comfortable by installing an aftermarket suspension. There are several designs available now, some for the front and others for the back. Monorim is a big name in this space, so I figured it would be hard to go wrong. Sadly, I did, and ended up taking a pass.

I tried their V3 front suspension for the G30, the one with the blue shock holder. After several test rides I did not feel safe enough on it for two main reasons. Here's my quick review of this promising yet disappointing aftermarket part.

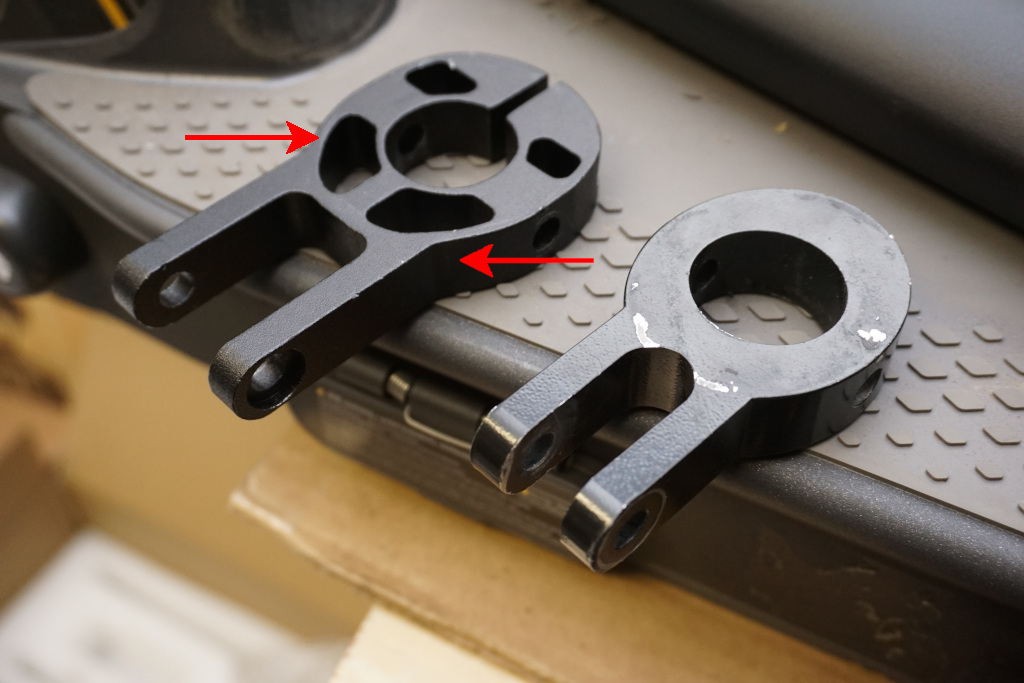

The top fork piece is fragile

I'm having a lot of trouble trusting the top fork-shaped part that fastens the top of the shock assembly to the stem of the scooter. Firstly, this part is made of aluminum instead of steel or iron per the magnet test (and its light weight). Its two arms that hold the shock are one hard bump away from snapping clean off. Then, the stem post would drop straight into the front wheel, causing it to lock up and you to go over the handlebars.

|

|

There are weak spots created by the bizarre decision to put holes in this part (red arrows on the left, above). I compared it to the equivalent in a generic M365 suspension (above right), and observed that it is actually one solid piece, and somewhat thicker than the G30 part.

In fact, I found the rod that goes through the G30 part is also improperly sized. It comes up a couple of mm short, creating a gap. This means even mild tightening of it would squeeze the two arms inward, further jeopardizing the integrity of the part.

If you consider the mechanics of this suspension kit, half of the scooter's weight rests on this part. Even though the spring aborbs a lot of bumps, these small aluminum take a lot of varying stress.

This part should be strengthened before I'd recommend anyone trust it.

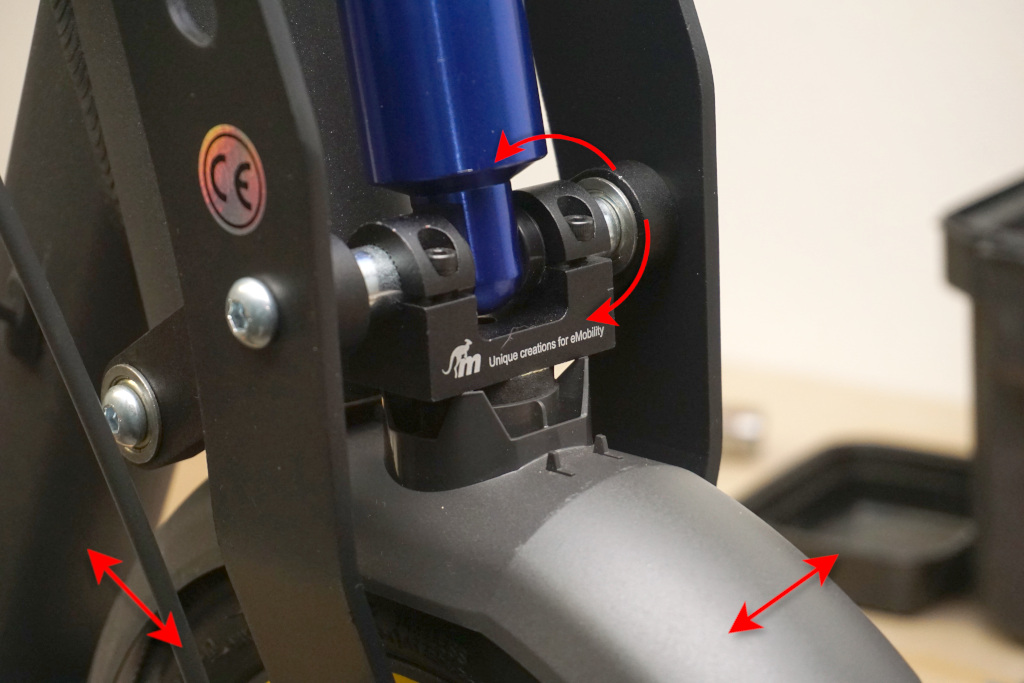

The fender bracket is flawed

During testing, I discovered my front wheel was rubbing against the plastic fender after hearing a strange sound. It goes without saying this is *not* great for safety.

What happened was that the fender had drifted forward as a result of the crossbar it was attached to slowly rotating.

I can only conclude Monorim didn't test this bracket whatsoever because its design is fundamentally flawed. It doesn't take an expert to realize that mounting something to a rod will result it in rotating with the rod.

There are some 3D printed solutions for this, but who knows how stable they would be. This one's pretty tough to excuse.

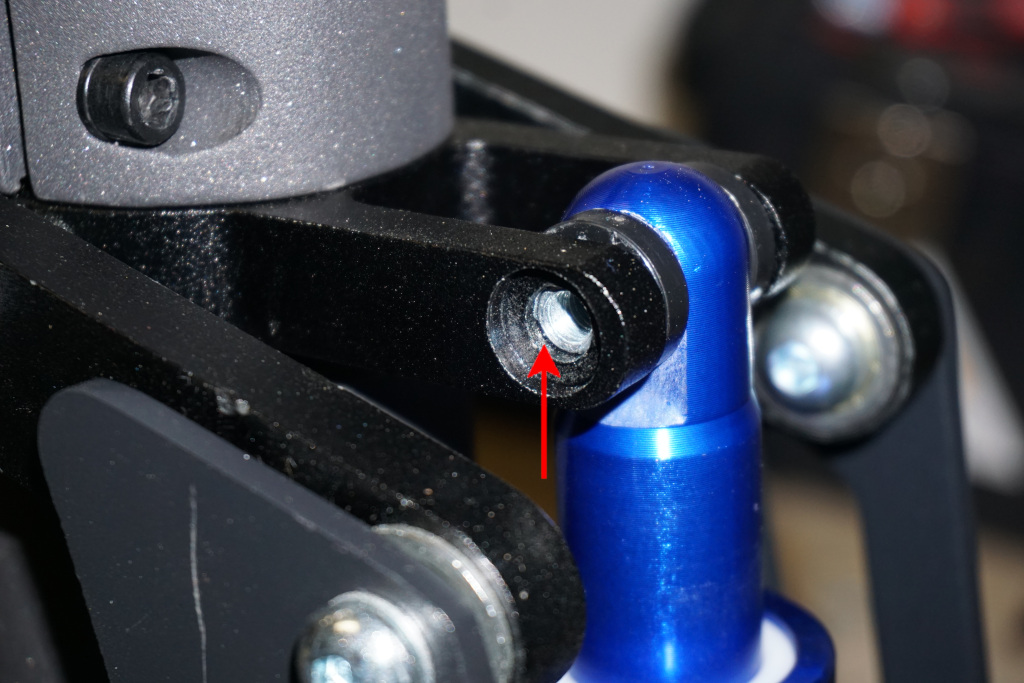

The column is too long

One common problem with the kit is stem wobble. It happens because the clamp securing the folding mechanism to this whole kit does not slide in far enough to push everything together. The kit's column is too long, so when you put that top bolt in, it ends up butting right up against the clamp (annontated in red below).

This causes the top fork piece below it to float freely. Unless you either push it down or use the stock ring as a spacer, the mechanism won't 'hug' the bearings tightly enough.

This is pretty easily addressable but a design flaw nonetheless.

The whole thing rattles

When moving I hear lots of new clicking and shaking noises. After looking into it, I believe the culprit is the shock assembly.

First, the spring inside of it floats freely and rattles all over the place. But the rods going through the holes above and below the cylinder also make noise because the fit is imperfect.